Because of food contamination, every year in the world

600M

people fall ill

420,000

people die

$100B

in economic losses

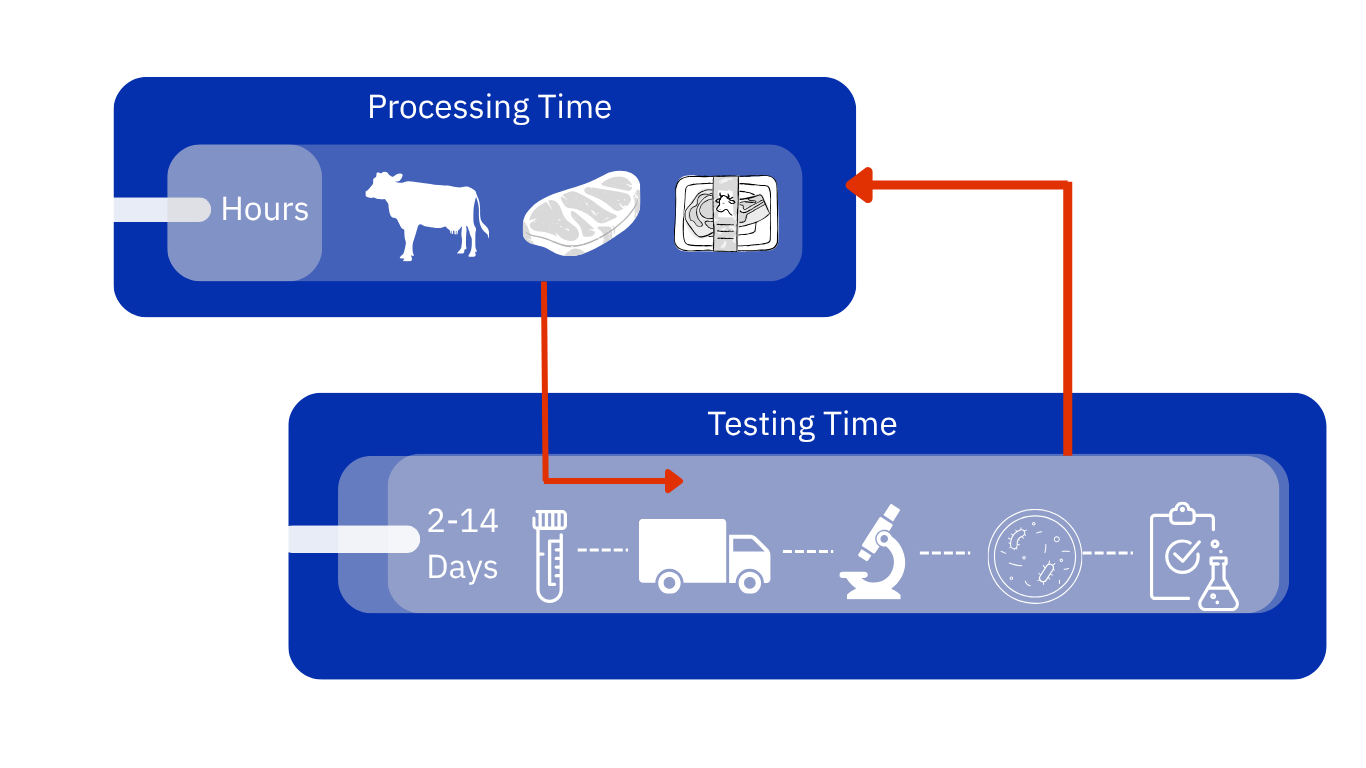

The Testing Dilemma—

Food processing is done in hours.

2 hours

Food testing requires days, because samples must be sent to a central lab for analysis.

Hypercell’s answer:

A simple, accurate, on-premise, micro-test that provides results in less than 1 hour with the precision of lab-based technologies.

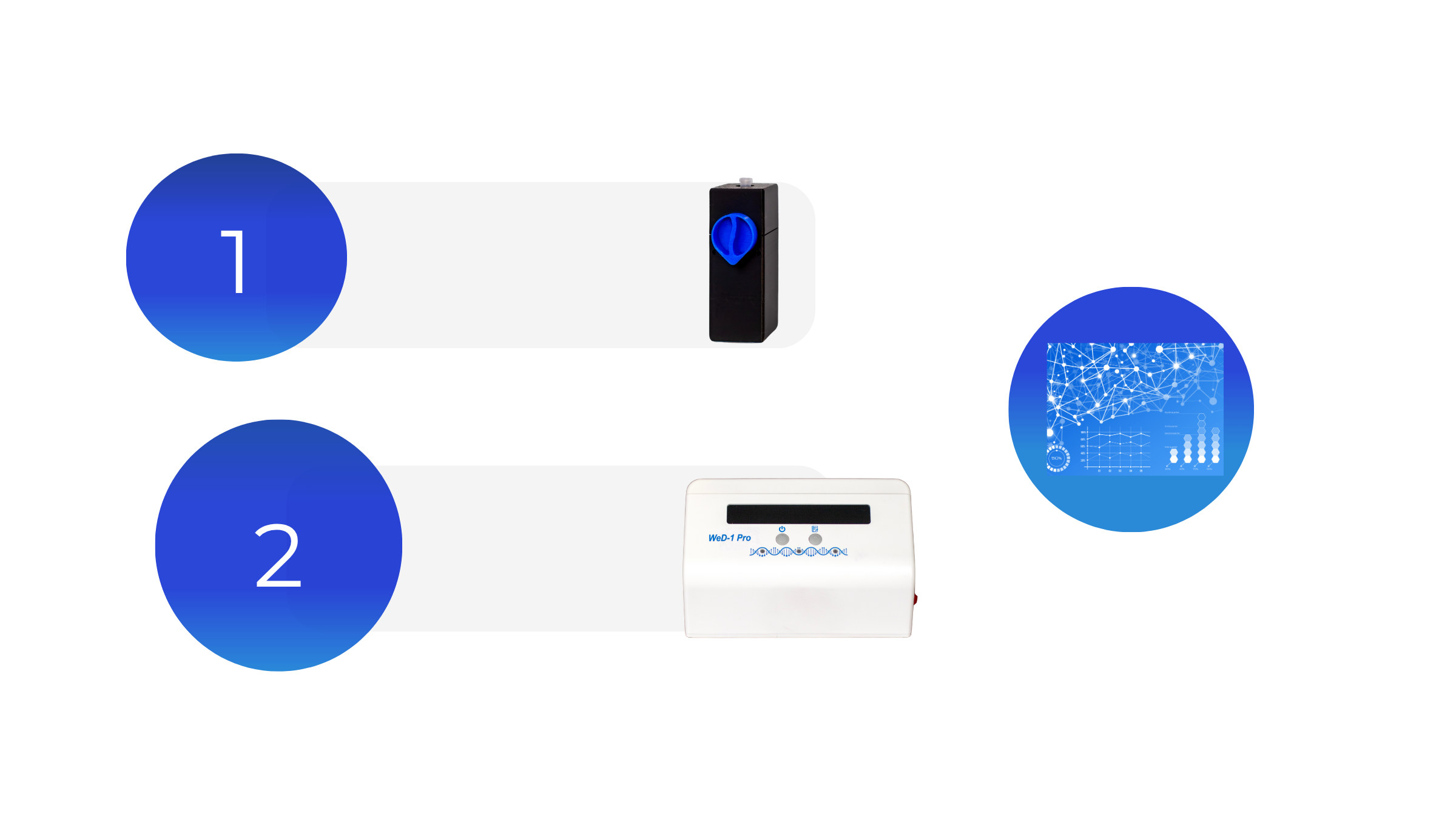

✔ Simple: 2-step process

✔ Rapid: results in less than 1 hour

✔ Accurate: highest level of accuracy

✔ Connected: SaaS platform

We’ve spent time in processing plants and with food safety teams, learning what features are most important in a test.

COMPROMISE

With current testing methods, you must choose between speed and accuracy.

NO COMPROMISE

With Hypercell, you can have both: speed and accuracy in a simple, easy to perform micro-test.

Food processors have said what they want in a diagnostic, by order of importance:

Rapid result turnaround time (TAT)

Ease of use

Accreditation or validation

Price

It’s a simple 2-step process

Capture

Detect

Results

That takes less than 30 minutes

What People Are Saying

“Hypercell checks all the boxes to drive industry-wide adoption .... Their technology provides results in minutes instead of hours or days in real world settings, and is easy enough for anyone to use.”

— Excerpt from IndieBio “Why We Invested”

Featured In

Awards

Accelerator Programs

SOSV IndieBio

2024

Plug & Play

2024

FoodBytes

2022