Environmental Monitoring for Contaminants

Ensure facilities are up to standard without delaying production.

For large processing plants, an hour of downtime costs around $1.1 million in lost revenue.

We’ve calculated that slow results contributes to the food industry losing close to $100B every year.

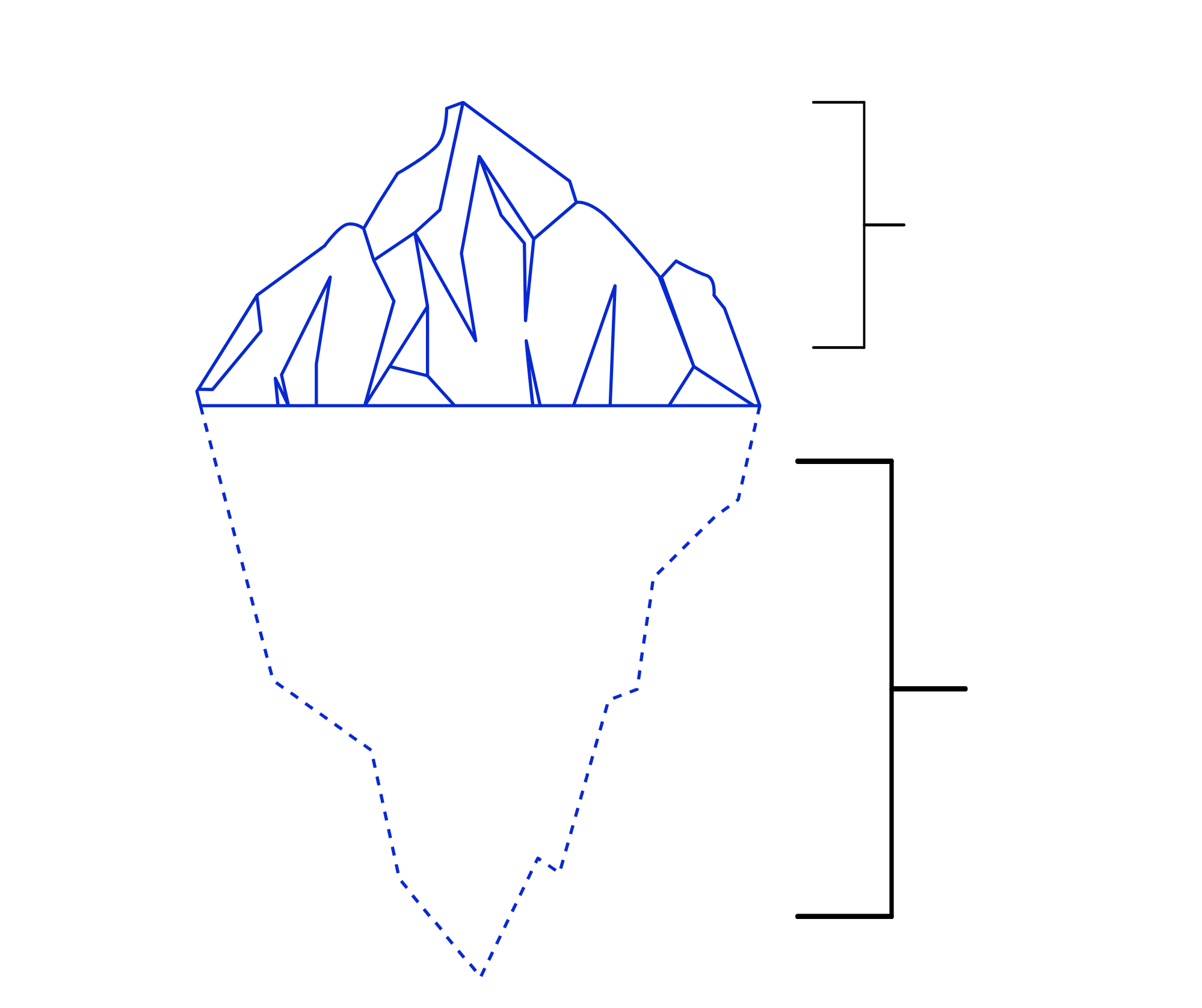

Most of the costs are “invisible” and linked to process inefficiencies and in-process contamination.

Product recalls

Reduced shelf life of fresh produce

Storage while waiting for test results

Legal action and settlements

Productivity loss

Wasted inventory from overly broad recalls and false alarms

Opportunity cost and delayed launches

Loss of business relationships

Diminishing returns on testing

Other Factors to Consider

The global food chain is increasingly complex, making contamination difficult to control.

1. Food products and ingredients are sourced from all over the world, meaning more handling, processing and transportation—complicating and increasing food safety risks.

2. Ready-to-eat foods and fresh and raw foods have higher food safety risks due to consumption without cooking.

3. Processed foods requires multiple steps, making food safety risks more complicated to manage.