Because of food contamination, every year in the world

600M

people fall ill

420,000

people die

$100B

in economic losses

The Testing Dilemma

Food processing is done in hours.

Food processing is done in hours.

Testing requires days.

2 hours

Food testing requires days, because samples must be sent to a central lab for analysis.

What happens during this waiting period?

Food manufacturers must wait to make critical product decisions, incurring costs, loss of valuable days of shelf life, risks of contaminated products shipped—resulting in recalls and brand damages and representing major economic losses.

Hypercell’s answer:

A simple, accurate, on-premise, micro-test that provides results in less than 1 hour with the precision of lab-based technologies.

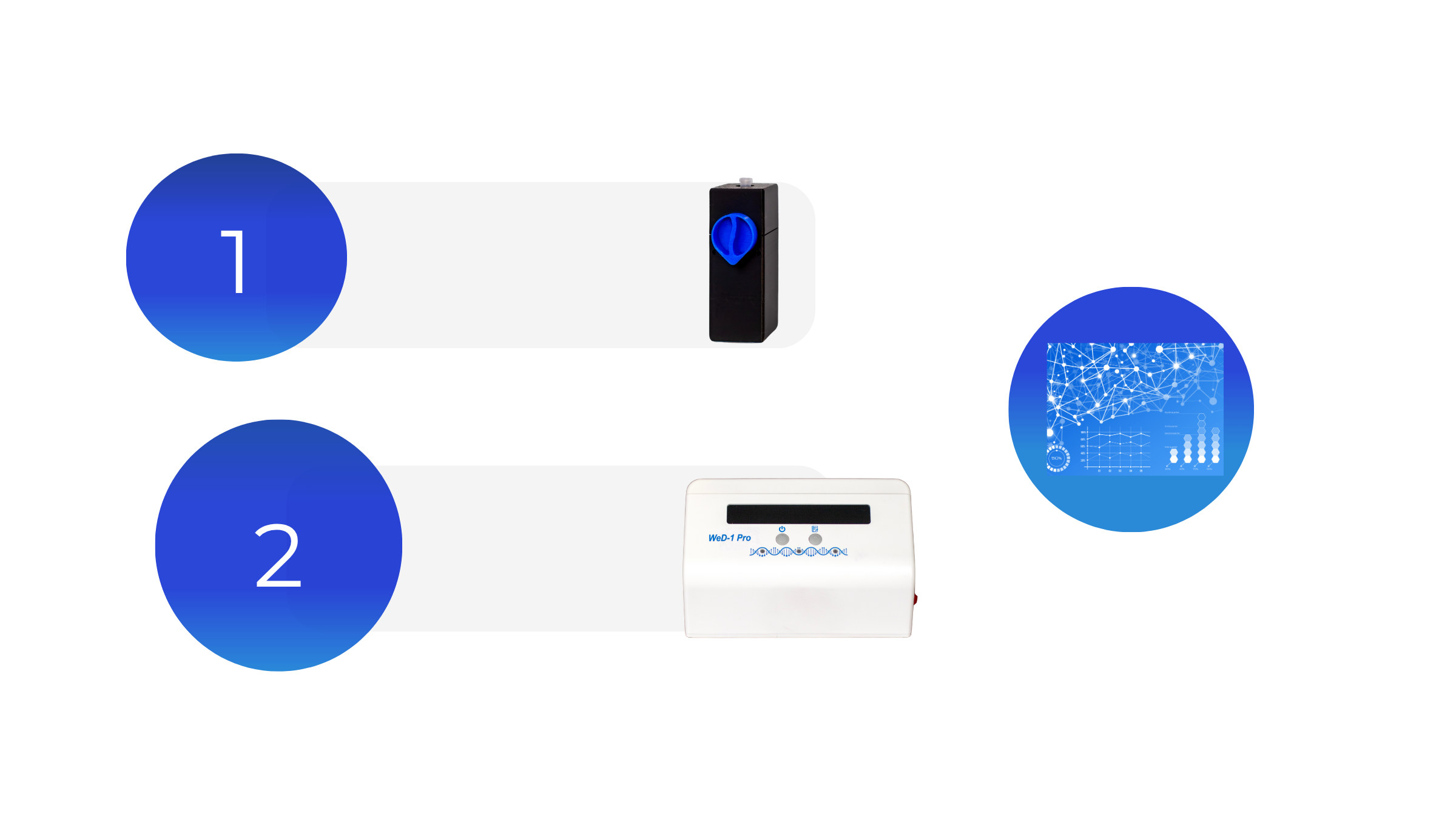

✔ Simple: 2-step process

✔ Rapid: results in less than 1 hour

✔ Accurate: highest level of accuracy

✔ Connected: SaaS platform

We’ve spent time in processing plants and with food safety teams, learning what features are most important in a test.

COMPROMISE

With current testing methods, you must choose between speed and accuracy.

NO COMPROMISE

With Hypercell, you can have both: speed and accuracy in a simple, easy to perform micro-test.

Food processors have said what they want in a diagnostic, by order of importance:

Rapid result turnaround time (TAT)

Ease of use

Accreditation or validation

Price

It’s a simple 2-step process

Capture

Detect

Results

That takes less than 30 minutes

What People Are Saying

“Hypercell checks all the boxes to drive industry-wide adoption .... Their technology provides results in minutes instead of hours or days in real world settings, and is easy enough for anyone to use.”

— Excerpt from IndieBio “Why We Invested”

Featured In

Awards

Accelerator Programs

SOSV IndieBio

2024

Plug & Play

2024

FoodBytes

2022